-

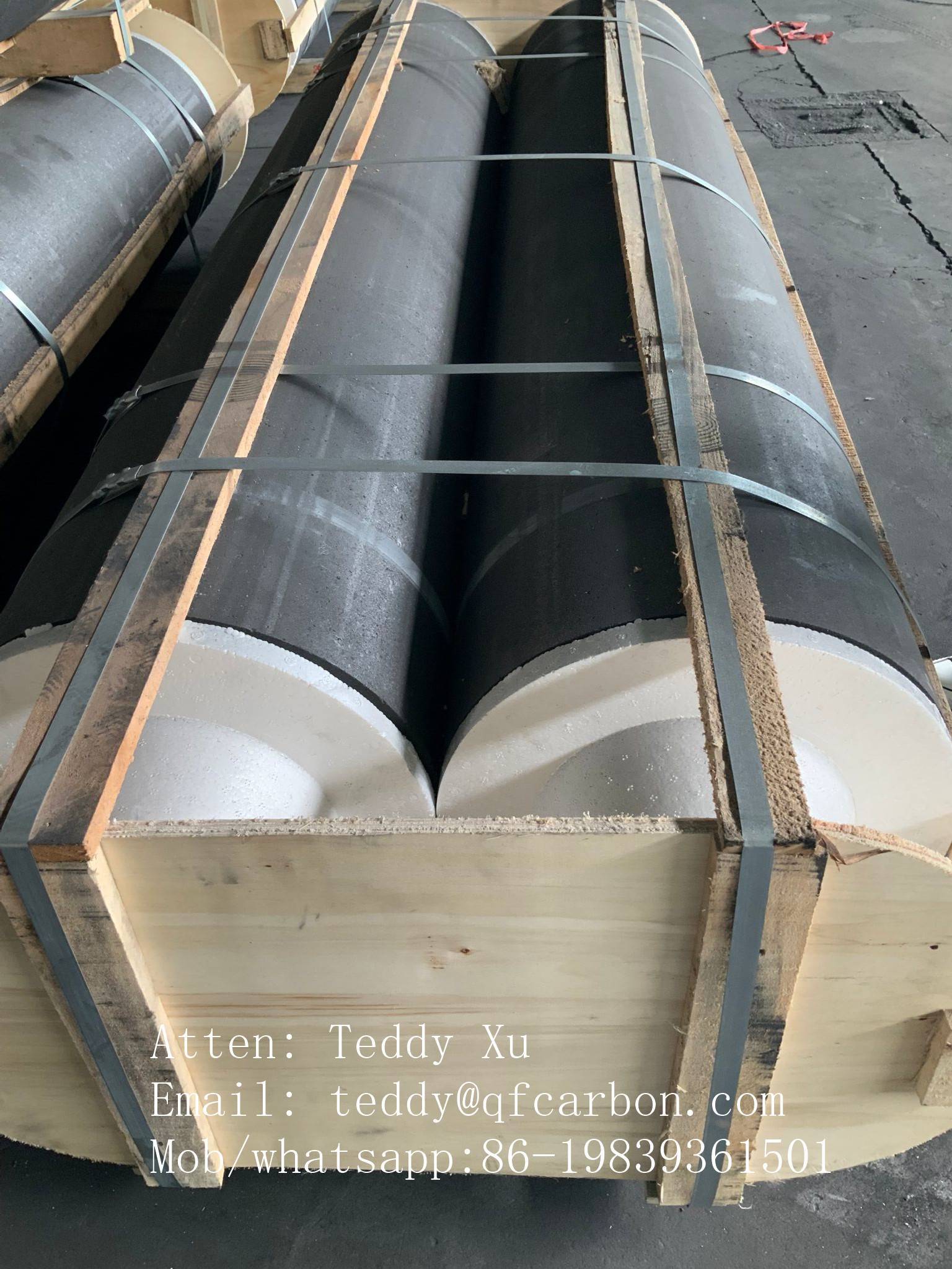

Graphite electrode market review and outlook

Market overview: The graphite electrode market as a whole shows a steady upward trend. Driven by the increase in raw material prices and the tight supply of ultra-high-power small and medium-sized graphite electrodes in the market, the price of graphite electrodes maintained a steady growth in J...Read more -

Graphitization bottlenecks gradually appear, graphite electrodes continue to rise steadily

This week, the domestic graphite electrode market price continued to maintain a steady and rising trend. Among them, UHP400-450mm was relatively strong, and the price of UHP500mm and above specifications was temporarily stable. Due to the limited production in Tangshan area, steel prices have re...Read more -

high quality characteristics about the graphite electrodes

As we all know, graphite has high quality characteristics that other metal materials can not replace. As the preferred material, graphite electrode materials often have many confusing characteristics in the actual selection of materials. There are many bases for choosing graphite electrode mater...Read more -

GRAPHITE ELECTRODES Manufacturing Process

1. RAW MATERIALS Coke (approximately 75-80% in content) Petroleum Coke Petroleum coke is the most important raw material, and it is formed in a wide range of structures, from highly anisotropic needle coke to nearly isotropic fluid coke. The highly anisotropic needle coke, due to its structure, ...Read more -

Data Analysis of Recarburizer

There are many kinds of raw materials of recarburizer, and the production process is also different. There are wood carbon, coal carbon, coke, graphite, etc., among which there are many small categories under various classifica...Read more -

Precautions for graphite electrodes

Precautions for graphite electrodes 1. Wet graphite electrodes should be dried before use. 2. Remove the foam protective cap on the spare graphite electrode hole, and check whether the internal thread of the electrode hole is complete. 3. Clean the surface of the spare graphite electrode and the ...Read more -

Advantages of graphite electrodes

Advantages of graphite electrodes 1: The increasing complexity of mold geometry and the diversification of product applications have led to higher and higher requirements for the discharge accuracy of the spark machine. The advantages of graphite electrodes are easier processing, high removal rat...Read more -

Raw materials continue to rise, graphite electrodes are gaining momentum

The domestic graphite electrode market price continued to rise this week. In the case of continuous increase in the ex-factory price of raw materials, the mentality of graphite electrode manufacturers is different, and the quotation is also confusing. Take the UHP500mm specification as an example...Read more -

Graphite Use In Electronics Applications

Graphite’s unique ability to conduct electricity while dissipating or transferring heat away from critical components makes it a great material for electronics applications including semiconductors, electric motors, and even the production of modern day batteries. 1. Nanotechnology and Semiconduc...Read more -

Application and performance of graphite electrode

Types for Graphite Electrode UHP (Ultra High Power); HP (high Power); RP( Regular Power ) Application for graphite Electrode 1) Graphite electrode material can be mainly used in electric furnace steelmaking. Electric furnace steelmaking uses graphite electrode to introduce working curre...Read more -

Whether the graphite mold market will replace the traditional mold market in 2021

In recent years, with the extensive use of graphite molds, the annual consumption value of the molds in the machinery industry is 5 times of the total value of all kinds of machine tools, and the huge heat loss is also very contrary to the existing energy-saving policies in China.The large consum...Read more -

Selection criteria for graphite electrode materials in 2021

There are many basis for selecting graphite electrode materials, but there are four main criteria: 1. The average particle diameter of the material The average particle diameter of the material directly affects the discharge status of the material. The smaller the average particle size of the mat...Read more