The working principle of ultra-high power graphite electrodes is to act as conductors for releasing electrical energy in an electric arc furnace, heating and melting the charge in the form of an electric arc.

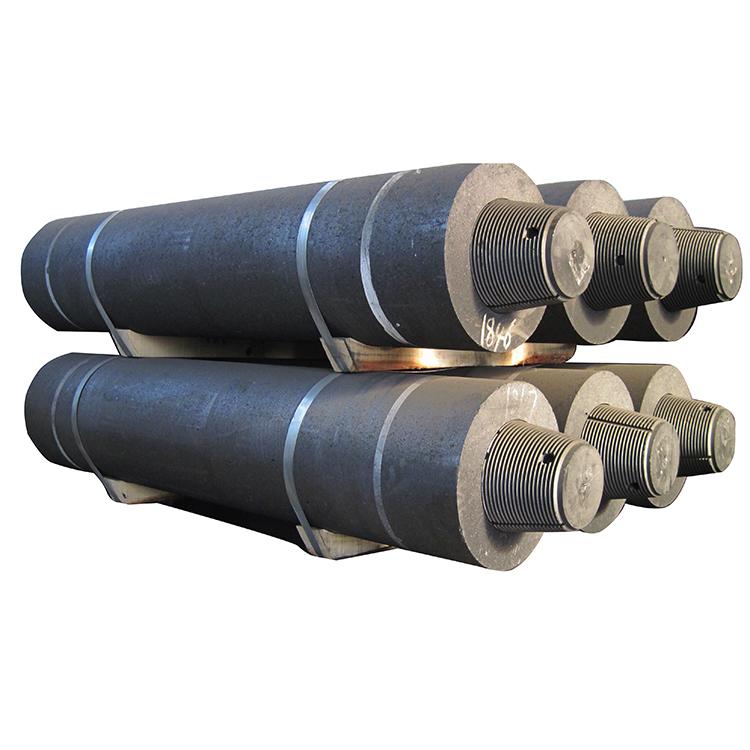

Ultra-high power graphite electrodes are made from raw materials such as petroleum coke and needle coke. After a series of complex processes including calcination, batching, kneading, pressing, roasting and graphitization, these materials form graphite electrodes with excellent electrical conductivity. During operation, an electric arc is generated at the lower end of the electrode. In this way, electrical energy is converted into thermal energy, thereby heating the charge and achieving the melting of metals or other substances.

Ultra-high power graphite electrodes are distinguished from ordinary power graphite electrodes because they can withstand a higher current density, which makes them particularly useful in situations where a larger power input is required. For instance, in the electric furnaces of industries such as steelmaking, silicon smelting, and yellow phosphorus smelting, ultra-high power graphite electrodes are widely used due to their excellent electrical conductivity and heat resistance.

Overall, ultra-high power graphite electrodes play a crucial role in industrial production. Their working capacity and reliability are essential for ensuring the stable operation of equipment such as electric arc furnaces.

Post time: Apr-24-2025