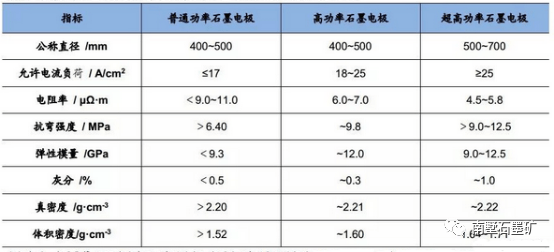

Graphite electrode refers to petroleum coke, needle coke as raw material, coal tar for adhesives, after raw material calcined, broken grinding, mixing, kneading, molding, calcination, impregnation, graphite and mechanical processing and made of a kind of high temperature resistance of graphite conductive material, called artificial graphite electrode (hereinafter referred to as graphite electrode), to distinguish it from the natural graphite as raw material preparation of natural graphite electrode. According to its quality index, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra-high power graphite electrode.

High power graphite electrode is made of high quality petroleum coke (or low grade needle coke) production, sometimes the electrode body needs to be impregnated, its physical and mechanical properties are higher than ordinary power graphite electrode, such as low resistivity, allowing a larger current density.

High power graphite electrode allows the use of current density of 18 ~ 25A/cm2 graphite electrode, mainly used in high power arc furnace steel making.

Electric furnace steelmaking is a major user of graphite electrodes. The output of eAF steel in China accounts for about 18% of the output of crude steel, and the graphite electrode used in steelmaking accounts for 70% ~ 80% of the total amount of graphite electrode. Electric furnace steelmaking is the use of graphite electrode into the furnace current, the use of electric extremes and charge between the arc generated by the high temperature heat source to smelting.

-arc furnace is mainly used in the production of industrial yellow phosphorus and silicon, etc., its characteristic is the lower part of the conductive electrode buried in furnace charge, arc formed within the material layer, and use the furnace charge itself from the resistance of the heat energy to heating furnace charge, one of the high current density required -arc furnace need graphite electrode, such as silicon 1 t per production to consumption of graphite electrode is about 100 kg, About 40kg of graphite electrode is needed to produce 1t yellow phosphorus.

The graphitization furnace for the production of graphite products, the melting furnace for melting glass and the electric furnace for the production of silicon carbide belong to the resistance furnace. The material in the furnace is both the heating resistance and the heating object. Usually, the conductive graphite electrode is embedded in the furnace wall at the end of the resistance furnace, and the graphite electrode is used for the discontinuous consumption here.

The blank graphite electrode is also used for processing various crucible, mold, boat and heating body and other special-shaped graphite products. For example, in the quartz glass industry, 10T of graphite electrode billet is needed for every 1T of electric fuse tube production; 100kg of graphite electrode billet is needed to produce 1t quartz brick.

From the beginning of the fourth quarter of 2016, with the promotion of supply-side reform policies in the iron and steel industry, cracking down on floor steel has suddenly become the top priority in eliminating backward production capacity. On January 10, 2017, vice Director of the National Development and Reform Commission said at the 2017 Council meeting of CISA that all floor bars should be removed before June 30, 2017. In 2017, China’s total capacity of eAF steel was about 120 million tons, of which 86.6 million tons were in production and 15.6 million tons were out of production. As of the end of October 2017, the production capacity of eAF was about 26.5 million tons, of which about 30% was resumed. Affected by the capacity reduction of medium frequency furnace, electric furnace steel is actively started, and the economic benefit of electric furnace steel is prominent. Electric furnace steel has a good demand for high power and ultra-high power graphite electrode, and high purchasing enthusiasm.

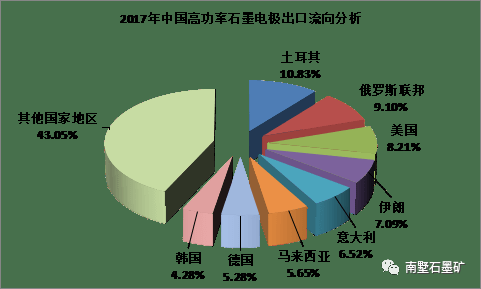

In 2017, the domestic price of graphite electrode soared, and the overseas demand rose. Both domestic and overseas markets returned to prosperity. In China, due to the clearance of “floor steel”, the increase of electric arc furnace capacity, environmental protection production limit of carbon enterprises and other factors, the domestic graphite electrode price skyrocketed in 2017, indicating that the domestic graphite electrode market is in short supply. At the same time, China’s graphite electrode growth shows that overseas graphite electrode demand is strong. Domestic and overseas have shown strong demand for graphite electrodes, the industry is still in short supply situation.

Therefore, the investment attraction of high power graphite electrode industry is still strong.

With the development of global iron and steel industry, electric arc furnace gradually to large, ultra-high power and computer automatic control and other aspects of development, the use of high power electric arc furnace is increasing, promote the application of high power graphite electrode.

Compared with the United States, Europe, Japan and other developed countries and regions, China’s high power graphite electrode industry started late, mainly relying on imports at the earliest, the production of high power graphite electrode is far from the demand. Driven by the development of iron and steel industry and technological progress, China has gradually broken the technological monopoly of foreign countries, and the production capacity of high power graphite electrode has been rising, and the product quality has also been rapidly improved. At present, the high power graphite electrode produced in China has achieved good results in large-scale electric arc furnace, and all the performance indexes of the product can reach the international leading level. China’s high power graphite electrode products not only supply the domestic market, but also a large number of exports to foreign countries, the demand for imported products is less.

The development of furnace steelmaking to high power is an important trend of the development of electric furnace steelmaking industry. In the future, the output of high power electric furnace steelmaking will increase, and its demand for high power graphite electrode will also increase, promoting the production of high power graphite electrode in China. Domestic high power graphite electrode enterprises can extend the industrial chain, carry out research and development of raw materials, and build production equipment, which can effectively reduce enterprise costs and improve enterprise operating profits.

Post time: May-31-2022