Carbon material production process is a tightly controlled system engineering, production of graphite electrode, special carbon materials, aluminum carbon, new high-end carbon materials are inseparable from the use of raw materials, equipment, technology, management of four production factors and related proprietary technology.

Raw materials are the key factors that determine the basic characteristics of carbon materials, and the performance of raw materials determines the performance of manufactured carbon materials. For the production of UHP and HP graphite electrodes, high quality needle coke is the first choice, but also high quality binder asphalt, impregnating agent asphalt. But only high quality raw materials, the lack of equipment, technology, management factors and related proprietary technology, is also unable to produce high quality UHP, HP graphite electrode.

This article focuses on the characteristics of high quality needle coke to expound some personal views, for needle coke manufacturers, electrode manufacturers, scientific research institutes to discuss.

Although the industrial production of needle coke in China is later than that of foreign enterprises, it has developed rapidly in recent years and has begun to take shape. In terms of total production volume, it can basically meet the demand of needle coke for UHP and HP graphite electrodes produced by domestic carbon enterprises. However, there is still a certain gap in the quality of needle coke compared with foreign enterprises. The fluctuation of batch performance affects the demand for high-quality needle coke in the production of large size UHP and HP graphite electrode, especially there is no high-quality joint needle coke that can meet the production of graphite electrode joint.

Foreign carbon enterprises producing large specifications UHP, HP graphite electrode is often the first choice of high-quality petroleum needle coke as the main raw material coke, Japanese carbon enterprises also use some coal series needle coke as raw material, but only for the following φ 600 mm specification of graphite electrode production. At present, the needle coke in China is mainly coal series needle coke. The production of high quality large-scale UHP graphite electrode by carbon enterprises often relies on imported petroleum series needle coke, especially the production of high quality joint with imported Japanese Suishima oil series needle coke and British HSP oil series needle coke as raw material coke.

At present, the needle coke produced by various enterprises is usually compared with the commercial performance indexes of foreign needle coke by conventional performance indexes, such as ash content, true density, sulfur content, nitrogen content, particle size distribution, thermal expansion coefficient and so on. However, there is still a lack of different grades of needle coke classification compared with foreign countries. Therefore, the production of needle coke colloquially also for “unified goods”, can not reflect the grade of high-quality premium needle coke.

In addition to conventional performance comparison, carbon enterprises should also pay attention to the characterization of needle coke, such as the classification of thermal expansion coefficient (CTE), particle strength, anisotropy degree, expansion data in non-inhibited state and inhibited state, and temperature range between expansion and contraction. Because these thermal properties of needle coke is very important to the control of graphitization process in the production process of graphite electrode, of course, the influence of the thermal properties of asphalt coke formed after roasting of binder and impregnating agent asphalt is not excluded.

1. Comparison of anisotropy of needle coke

(A) Sample: φ 500 mm UHP electrode body of A domestic carbon factory;

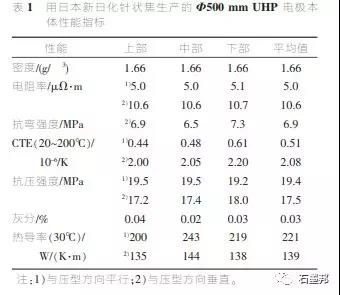

Raw material needle coke: Japanese new Chemical LPC-U grade, ratio: 100%LPC-U grade; Analysis: SGL Griesheim plant; Performance indicators are shown in Table 1.

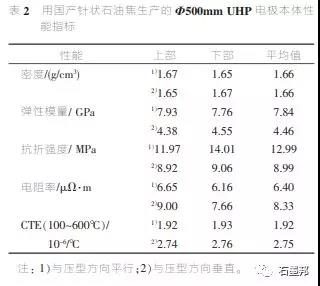

(B) Sample: φ 450 mmHP electrode body of a domestic carbon factory; Raw material needle coke: a domestic factory oil needle coke, ratio: 100%; Analysis: Shandong Bazan Carbon Plant; Performance indicators are shown in Table 2.

As can be seen from the comparison of Table 1 and Table 2, the lPC-U grade of needle coke of new daily chemical coal measures has a large anisotropy of thermal properties, in which the anisotropy of CTE can reach 3.61~4.55, and the anisotropy of resistivity is also large, reaching 2.06~2.25. Besides the flexural strength of domestic petroleum needle coke is better than that of new daily chemical LPC-U grade coal measure needle coke. The value of anisotropy is much lower than that of new Daily chemical LPC-U coal measure needle coke.

Ultra high power graphite electrode production anisotropic degree performance analysis is the estimation of needle coke raw material quality or not an important analysis method, the size of the degree of anisotropy, of course, also have a certain influence on electrode production process, the degree of anisotropy of electricity extremely thermal shock performance than the anisotropy degree of the average power of the small electrode is good.

At present, the production of coal needle coke in China is much larger than that of petroleum needle coke. Due to the high raw material cost and price of carbon enterprises, it is difficult to use 100% domestic needle coke in the production of UHP electrode, while adding a certain proportion of calcted petroleum coke and graphite powder to produce electrode. Therefore, it is difficult to evaluate the anisotropy of domestic needle coke.

2. Linear and volumetric properties of needle coke

The linear and volumetric change performance of needle coke is mainly reflected in the graphite process produced by the electrode. With the change of temperature, the needle coke will undergo linear and volumetric expansion and contraction during the process of graphite process heating up, which directly affects the linear and volumetric change of the electrode roasted billet in the graphite process. This is not the same for the use of different properties of raw coke, different grades of needle coke changes. Moreover, the temperature range of linear and volume changes of different grades of needle coke and calcined petroleum coke is also different. Only by mastering this characteristic of raw coke can we better control and optimize the production of graphite chemical sequence. This is especially evident in the series graphitization process.

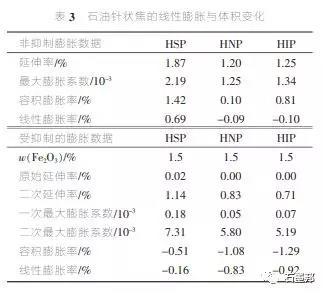

Table 3 shows the linear and volume changes and temperature ranges of three grades of petroleum needle coke produced by Conocophillips in the UK. Linear expansion occurs first when oil needle coke begins to heat up, but the temperature at the beginning of linear contraction usually lags behind the maximum calcination temperature. From 1525℃ to 1725℃, linear expansion begins, and the temperature range of the whole linear contraction is narrow, only 200℃. The temperature range of the whole line contraction of the ordinary delayed petroleum coke is much larger than that of the needle coke, and the coal needle coke is between the two, slightly larger than the oil needle coke. The test results of Osaka Industrial Technology Test Institute in Japan show that the worse the thermal performance of coke, the greater the line shrinkage temperature range, up to 500 ~ 600℃ line shrinkage temperature range, and the start of the line shrinkage temperature is low, at 1150 ~ 1200℃ began to occur line shrinkage, which is also the characteristics of ordinary delayed petroleum coke.

The better the thermal properties and the greater the anisotropy of needle coke, the narrower the temperature range of linear contraction. Some high-quality oil needle coke only 100 ~ 150℃ linear contraction temperature range. It is very beneficial for carbon enterprises to guide graphitization process production after understanding the characteristics of linear expansion, contraction and reexpansion of various raw materials coke, which can avoid some unnecessary quality waste products caused by using the traditional experiential mode.

3 conclusion

Master the various characteristics of raw materials, choose reasonable equipment matching, good combination of technology, and the enterprise management is more scientific and reasonable, this series of whole process system tightly controlled and stable, can be said to have the basis of producing high-quality ultra-high power, high power graphite electrode.

Post time: Dec-30-2021