The main application field of calcined coke in China is electrolytic aluminum industry, accounting for over 65% of the total amount of calcined coke, followed by carbon, industrial silicon and other smelting industries. The use of calcined coke as fuel is mainly in cement, power generation, glass and other industries, accounting for a small proportion.

At present, the domestic supply and demand of calcined coke is basically the same. However, due to the export of a large amount of low-sulfur high-end petroleum coke, the total domestic supply of calcined coke is insufficient, and it still needs to import medium and high sulfur calcined coke for supplement.

With the construction of a large number of coking units in recent years, the output of calcined coke in China will be expanded.

Depending on the sulfur content, it can be divided into high sulfur coke (sulfur content above 3%) and low sulfur coke (sulfur content below 3%).

Low sulfur coke can be used as anodic paste and pre-baked anode for aluminum plant and graphite electrode for steel plant.

The high quality low sulfur coke (sulfur content less than 0.5%) can be used to produce graphite electrode and carbonizing agent.

Low sulphur coke of general quality (sulphur content less than 1.5%) is commonly used in the production of pre-baked anodes.

Low quality petroleum coke is mainly used in smelting industrial silicon and anodic paste production.

High-sulfur coke is commonly used as fuel in cement plants and power plants.

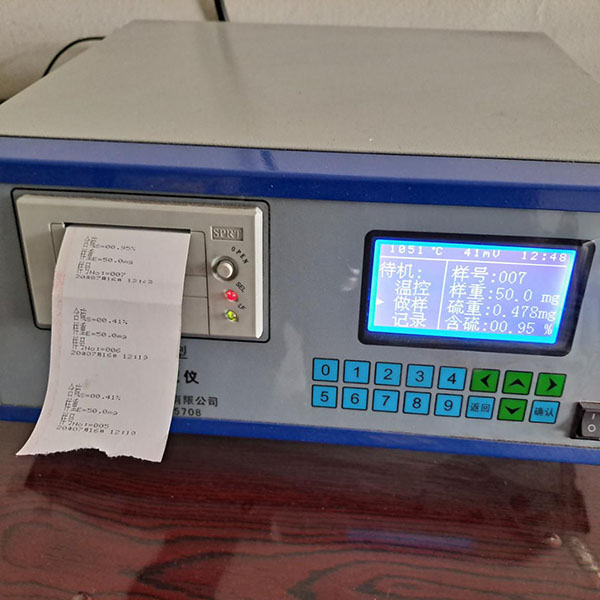

Continuous and exact sampling and testing is an integral part of our production process.

High sulfur coke may cause gas bloating during graphitization, resulting in cracks in carbon products.

High ash content will hinder the crystallization of the structure and affect the performance of carbon products

Every step will be carefully tested, we want to do is exactly the detection data.

As part of our quality system every package will be weighed at least 3 times, to avoid any discrepancies.

Without green calcined coke resistivity is very high, close to the insulator, after calcining, resistivity fell sharply, is inversely proportional to the resistivity of petroleum coke and calcined temperature, after 1300 ℃ of calcined petroleum coke resistivity decreased to 500 μm Ω m. or so.

Post time: Dec-20-2024