High Quality Uhp Graphite Electrode - UHP700mmX2700mm Graphite Electrode for Steel Melt/Arc Furnaces – Qifeng

High Quality Uhp Graphite Electrode - UHP700mmX2700mm Graphite Electrode for Steel Melt/Arc Furnaces – Qifeng Detail:

Supply Ability

3000 Tons per Month

Packing & Delivery

Packaging Details: Standard wooden pallets or according to customer’s requirement.

Port: Tianjin Port

Composition Of Graphite Electrode

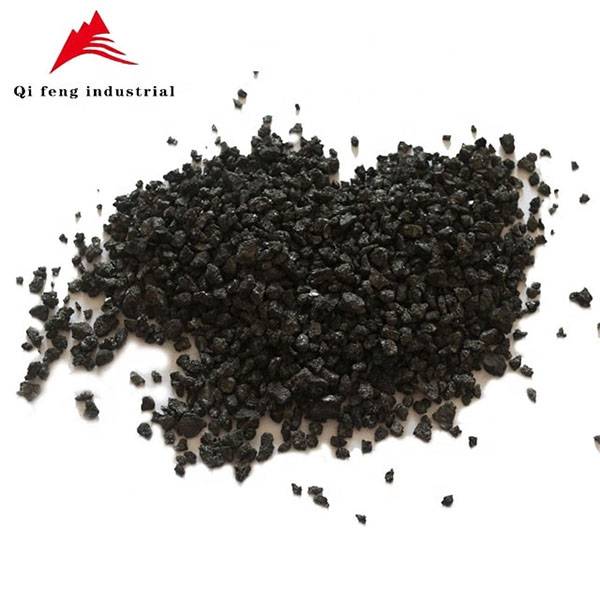

Graphite electrode mainly use petroleum coke, needle coke as raw material, coal asphalt binder, calcination, ingredients, kneading, molding, baking and graphitization, machining and made, which is released in electric arc furnace in the form of arc conductor of electricity to heat melting furnace charge, according to its quality index, can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.The main raw material of graphite electrode production is petroleum coke, ordinary power graphite electrode can add a small amount of asphalt coke, petroleum coke and asphalt coke sulfur content can not exceed 0.5%.Needle coke is also needed to produce high power or ultra high power graphite electrodes.The main raw material for aluminum anode production is petroleum coke, and the sulfur content should not exceed 1.5% ~ 2%.

Product detail pictures:

Related Product Guide:

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for High Quality Uhp Graphite Electrode - UHP700mmX2700mm Graphite Electrode for Steel Melt/Arc Furnaces – Qifeng, The product will supply to all over the world, such as: Mauritius, Uganda, Nepal, because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.